Beverage processing plant

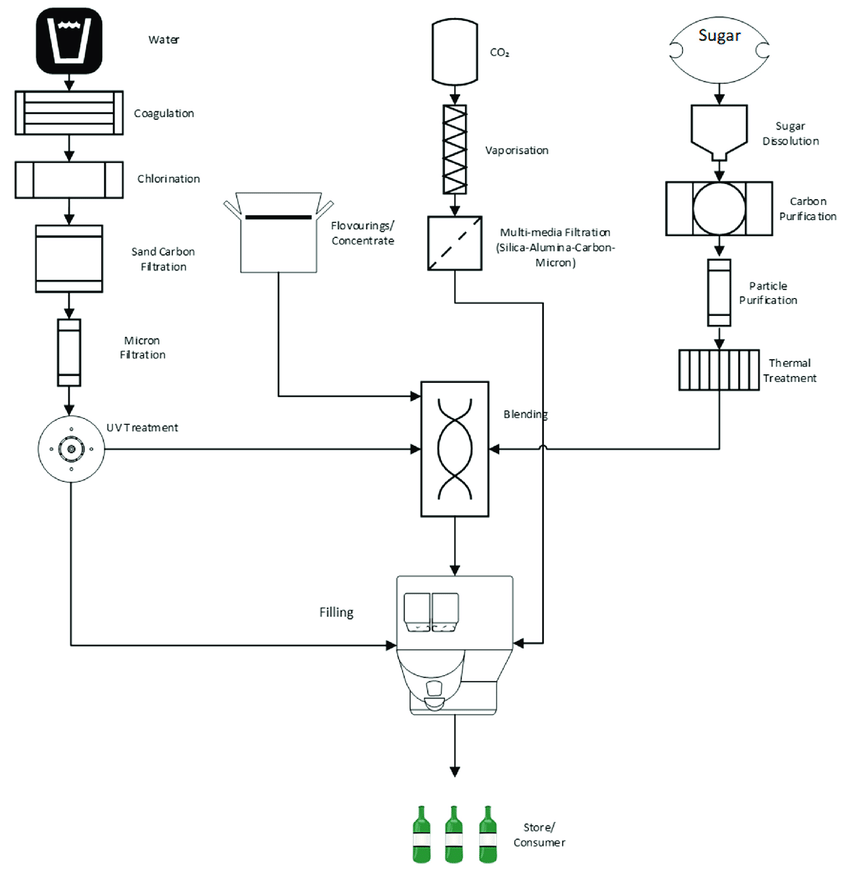

The process of producing beverages in a processing plant typically involves several stages. Here are some of the common stages in the beverage production process:

1. Raw Material Preparation: The first stage involves the preparation of the raw materials, such as fruits, vegetables, or grains. The raw materials are sorted, cleaned, and washed to remove any debris or dirt.

2. Extraction: In this stage, the juice or extract is extracted from the raw material using various methods such as pressing, crushing, or grinding.

3. Filtration: The extracted juice or extract is then filtered to remove any solids, pulp, or debris.

4. Mixing and Blending: Once the juice or extract is filtered, it is mixed with other ingredients such as water, sugar, or flavors to create the desired taste and consistency.

5. Pasteurization: The mixture is then heated to a specific temperature to kill any harmful bacteria and extend the shelf life of the beverage.

6. Carbonation: If the beverage is carbonated, carbon dioxide is injected into the mixture to create the desired level of carbonation.

7. Bottling and Packaging: Once the beverage is prepared, it is bottled and packaged in a suitable container for distribution to retailers and consumers.

8. Quality Control: Throughout the production process, quality control measures are implemented to ensure that the beverage meets certain standards for taste, texture, and appearance. This can include laboratory testing of samples, as well as sensory evaluation by trained tasters.